Utilizing waste as a resource, LG Chem’s chemical recycling technology! Interview with the Recycle strategy team

2023. 12. 27

2023. 12. 27

Plastic recycling is an all-time hot issue. People make efforts to practice recycling in life, yet the world’s plastic recycling rate remains under 10% (as of 2019). According to OECD’s Global Plastic Outlook, only 9% out of all plastic wastes was recycled in 2019, and about 50% was sent to sanitation landfill. As a response, companies are taking the head to improve the plastic recycling rate. LG Chem is committed to resource recovery from waste plastics by producing PCR (Post-Consumer Recycled) materials through mechanical recycling. For plastics that cannot be recycled by this method, we also apply our chemical recycling technology.

And here is one person who brings all these efforts into his job. This man visits the garbage dump to look for waste plastics that are to become the raw material for chemical recycling. Today, we invite Specialist Kim Dong-hyun from LG Chem’s Recycle strategy team to hear his talk about chemical recycling.

Hello! Please introduce yourself.

Hello, I’m Specialist Kim Dong-hyun from LG Chem’s Sustainability Business Department, in specific, the Recycle Strategy Team. I’m in charge of Circular Recycling Supply Chain Management (CR SCM).

What does the Recycle Strategy Team do?

My team’s job is related to the construction of CR (Chemical Recycling) plants. We make sure that we have a stable supply of waste plastics that fit the spec required for use as a feed stock, and establish the Binding between raw material suppliers and LG Chem. We make business trips to different raw material suppliers and set up plans on how to produce raw materials that fit our required spec. We also deal with diverse tasks such as examining new raw materials besides waste plastics, for instance, ocean wastes.

What responsibility do you have, and what does your normal day look like?

Among many recycling companies, I work to discover manufacturers who can produce raw materials from waste plastics that fit the chemical recycling Spec required by LG Chem. Once found, I establish a Binding so that we can use their productions in LG Chem’s chemical recycling plants. To do this, I visit garbage dumps and recycling companies around the country to take various samples, and request analysis of those samples at a research center to confirm the results.

What exactly is chemical recycling?

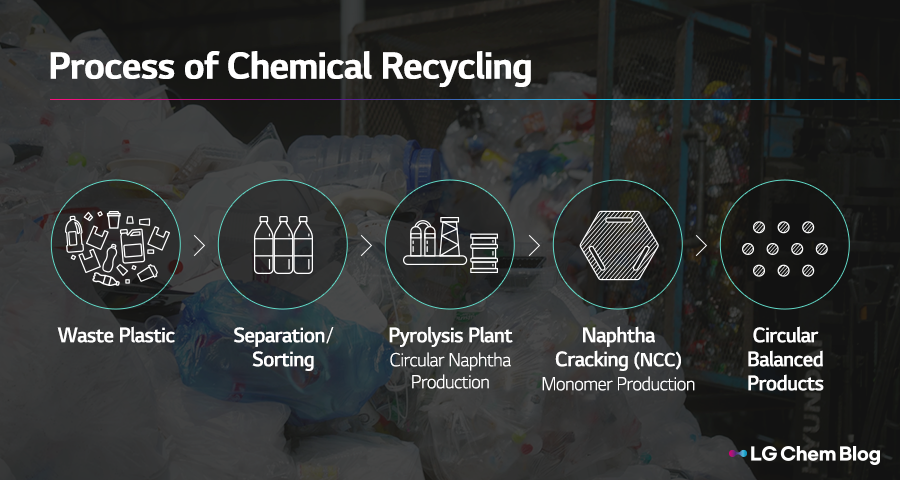

To put it simply, chemical recycling is ‘an essential technology needed to utilize wastes as a resource.’ Could we recycle take-out containers that have food stains on them? The answer is, it’s impossible with mechanical recycling but possible with chemical recycling! The vinyl products that we use in everyday life can be an important resource for chemical recycling. This includes mostly PP and PE, and not just vinyl types but also solid types. Waste vinyl is usually a composite material that is hard to sort, and despite its high volume, it hardly weighs anything, which creates a nuisance for recycling companies. However, at LG Chem’s chemical recycling plants, we pyrolyze PP and PE to produce pyrolysis oil. This oil is then refined to a naphtha-like form. By investing the oil into LG Chem’s NCC plants, we can create various types of chemically-recycled plastics, and this is how LG Chem’s chemical recycling technology works. To put it easily, it’s a technology of breaking down plastics under high temperature/pressure and turning them into a raw material for new plastics.

Compared to mechanical recycling, chemical recycling poses more technological difficulties and higher initial-investments. However, there is brighter prospect in terms of its marketability since it has no limitation in physical changes or the number of recycling. The global chemical recycling market, based on the amount of pyrolysis oil extracted from waste plastics, is expected to grow from 700,000 tons in 2020 to 3.3 million tons in 2030 by an average of over 17% every year.

LG Chem is focusing our capabilities on securing the chemical recycling technology. Currently underway is the construction of a pyrolysis plant in Dangjin, South Chungcheong Province, Korea. Due to begin operation in 2024, the pyrolysis plant is expected to become a central basis for establishing the plastic circular economy by producing Circular-Balanced products through chemical recycling.

Share with us an episode of visiting the fields.

Roaming around the garbage dumps all day long, the smell of garbage often clings to my body. I was returning home on a train one day, when the passersby avoided me like a homeless man. In fact, when I visit the centers, I usually wear shabby clothes that I can throw out any time, and don’t care about my hairdo, either. Together with the strong odor, I probably caused a misunderstanding.

What are some goals of the Recycle strategy team?

As LG Chem gets to operate Korea’s first large-scale commercial pyrolysis plant, my team’s short-term goal is to tune with the raw material suppliers that we’ve discovered and make sure the wastes are supplied to chemical recycling plants without an issue. Our long-term goal is to promote LG Chem’s chemical recycling business so that recycling can settle deeper into our everyday lives. Ultimately, we hope to enhance Korean citizens’ consciousness about recycling. If we perceive the importance of recycling at our homes and workplaces, and pay extra attention to separation/sorting when discarding garbage, I believe recycling companies will have more quality-wastes (well-separated or well-sorted wastes) to recycle them as much as possible.

How did you enjoy the interview with Specialist Kim Dong-hyun who visits garbage dumps in search of raw materials for chemical recycling? LG Chem is putting great efforts into creating sustainable materials that benefit the Earth, including the production of Circular Balanced plastics based on chemical recycling technology. Until LG Chem’s pyrolysis oil plant is completed, please keep your support for LG Chem’s environmental actions!

There are no comments yet! Be the first to let us know your thoughts!