FOCUS ON: Single-Crystal High-Nickel Cathode

2024. 02. 28

FOCUS ON: Single-Crystal High-Nickel Cathode

2024. 02. 28

There’s a change of wind in the battery industry. Consistent efforts are being made to overcome the weaknesses and limits of traditional batteries. ‘FOCUS ON’ takes a close look at one product at a time. Today’s focus will be Single-Crystal High-Nickel Cathode, which is gaining recognition as a next-generation battery material with improved battery capacity, lifespan, and production costs.

Cathode is the energy source of a lithium-ion battery, which determines the efficiency and capacity of a battery. To learn more about cathode, refer to the ‘LG Chem, a leader in the market for battery materials! Find out how the company built a plant to produce 120,000 tons of cathode materials each year’ content.

What is a Single-Crystal High-Nickel Cathode? Let’s look at the term ‘High-Nickel’ first.

What is a Single-Crystal High-Nickel Cathode? Let’s look at the term ‘High-Nickel’ first.

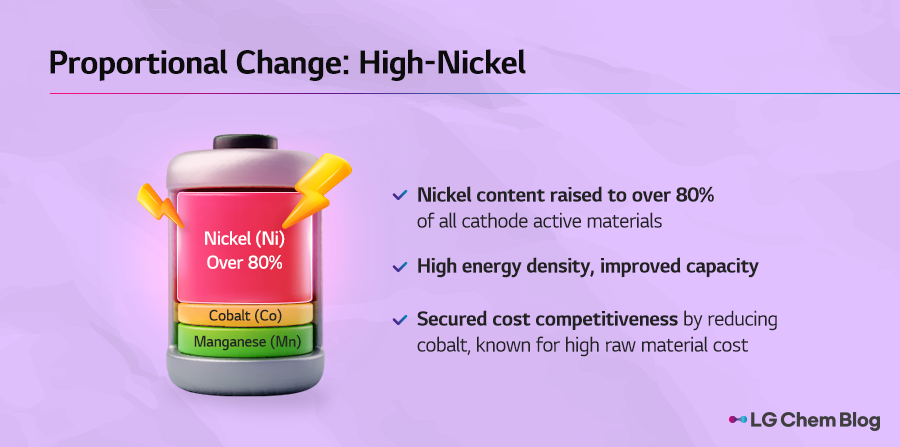

Cathode is subdivided into NCM, NCMA, NCA, and LFP, depending on which cathode active material it contains. Among these types, EV batteries commonly use NCM, which consists of Nickel (Ni), Cobalt (Co), and Manganese (Mn). High-Nickel Cathode gained its name by lowering the proportion of cobalt and raising the nickel content to over 80%. For instance, NCM811 is a High-Nickel Cathode that contains Nickel, Cobalt, and Manganese by 8:1:1 ratio.

While Manganese and Cobalt determine the safety of a Cathode, Nickel is a metal that determines its capacity. The higher the Nickel content, the bigger number of lithium cells can enter through the lithium layer compared to other metals. Therefore, high nickel content brings raised energy density, improving the battery capacity.

Another great advantage that High-Nickel cathode offers is the reduced production cost. Cobalt has the highest cost of all battery raw materials. By lowering the cobalt content, we can hedge against the fluctuation in raw material costs and secure cost competitiveness.

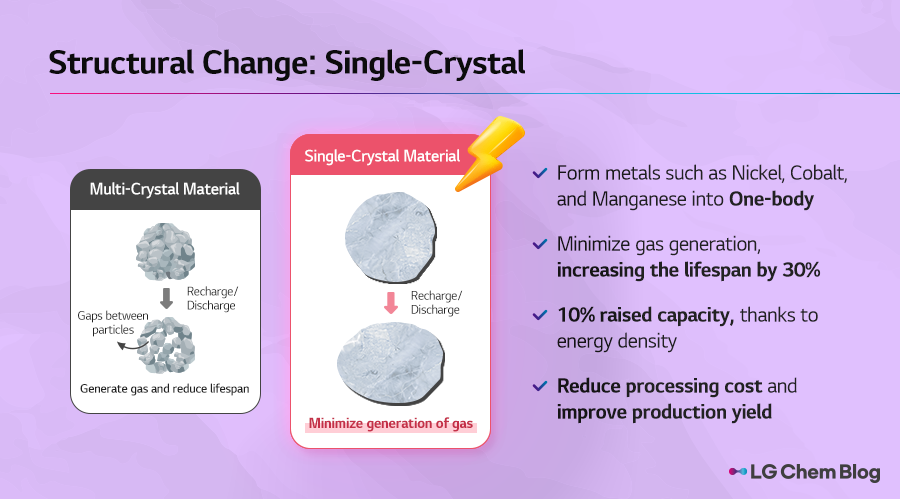

Next, what is a Single-Crystal Cathode? It refers to a material that contains different metals, such as Nickel, Cobalt, and Manganese, formed into One-body. Also called Single-Particle Cathode, it is counted on as the game-changer to solve the issues of battery lifespan and capacity, which are the core tasks of next-generation batteries.

Conventional Cathode had a Multi-crystal (Multi-particle) structure made by joining small metal particles. However, as it kept recharging and discharging, gaps were formed between each particle, generating gas and losing its battery lifespan. At times, it also caused battery swelling.

Single-Crystal Cathode, however, is made by joining numerous metal particles into One-body. Since it generates less gas, it has higher safety and battery lifespan lengthened by 30%. On top of that, it has over 10% increased capacity, since Single-Crystal Cathode has higher density compared to conventional materials. For example, let’s say an EV that has conventional cathode runs 500km per charge. With a same-sized and same-weighted battery made of Single-Crystal Cathode, the range is increased to over 550km.

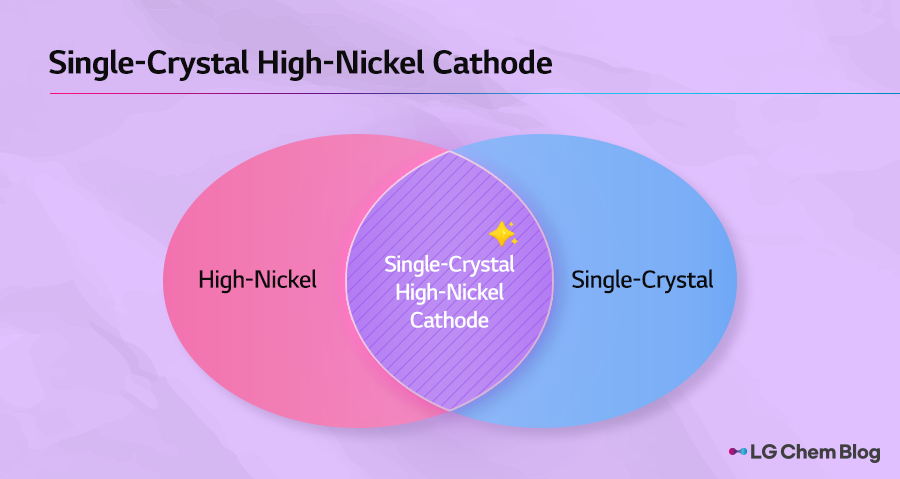

In short, Single-Crystal High-Nickel Cathode is a next-generation battery material with improved battery capacity and lifespan, which maximizes Nickel content out of all metals that form a cathode (Proportional change: High-Nickel). Also, these metals are formed into a One-body structure (Structural change: Single-Crystal).

In June 2023, LG Chem began Korea’s first mass-production of Single-Crystal High-Nickel Cathode. At the initial stage of production which takes place in Cheongju, Korea, we plan to produce Single-Crystal Cathode and conventional cathode by a 2:8 ratio and gradually switch to 100% Single-Crystal Cathode production. The application will also start from a pouch-type product and diversify to 4680 cylindrical battery (diameter 45mm·length 80mm), etc.

Today, we focused on the next-generation battery material, Single-Crystal High-Nickel Cathode. Please keep your support for LG Chem and the Single-Crystal High-Nickel Cathode, as we expand our leadership in the global battery materials market.

There are no comments yet! Be the first to let us know your thoughts!