Creating New Plastics by Utilizing Waste Plastics! Interview with Researchers in PCR ABS Product Development

2023. 05. 07

2023. 05. 07

LG Chem has embarked on a project focused on researching and developing innovative plastic materials through the recycling of waste plastics. Among our notable research achievements is the development of PCR (Post-Consumer Recycle) ABS, a plastic product that matches the properties of traditional plastics. Leveraging our pioneering technological capabilities in the chemical industry, we have successfully produced recycled plastics in white color. Recycling waste plastics is considered the most expedient approach to achieving our goal of reducing carbon emissions by 2050, and its significance is expected to grow even further in the future. Now, let’s meet two researchers from this project who have been aligning with market trends, prioritizing eco-friendly circularity, and diligently developing and researching products to meet the needs of customers. Are you ready to dive into their insightful story? Take a look at the interview from our researchers!

Hello! Please introduce yourself and tell us about your current responsibilities.

•Seo-Hwa Kim, PL: Hello, I’m Seo-Hwa Kim, responsible for ABS material development at the Styrenics Center, HME PJT, within LG Chem’s Petrochemical Research Institute. My research primarily focuses on developing PCR ABS using waste plastics as raw materials. Additionally, I work on creating materials that can achieve the popular metallic look in high-end home appliances without the need for coating processes. Furthermore, I’m involved in developing extrusion materials with improved chemical resistance for refrigerators, incorporating environmentally friendly foaming agents.

•Chang-Sul Kim, Team Leader: Hello, I’m Chang-Sul Kim, a team leader in the Product Planning Team of the ABS Business Division at LG Chem’s Petrochemical Business Headquarters. My responsibilities involve product planning for materials used in home appliances, electrical and electronic products. Within our team, we analyze the characteristics and regulatory requirements of plastics for various applications. We collaborate closely with the research and development department to identify and propose marketable materials.

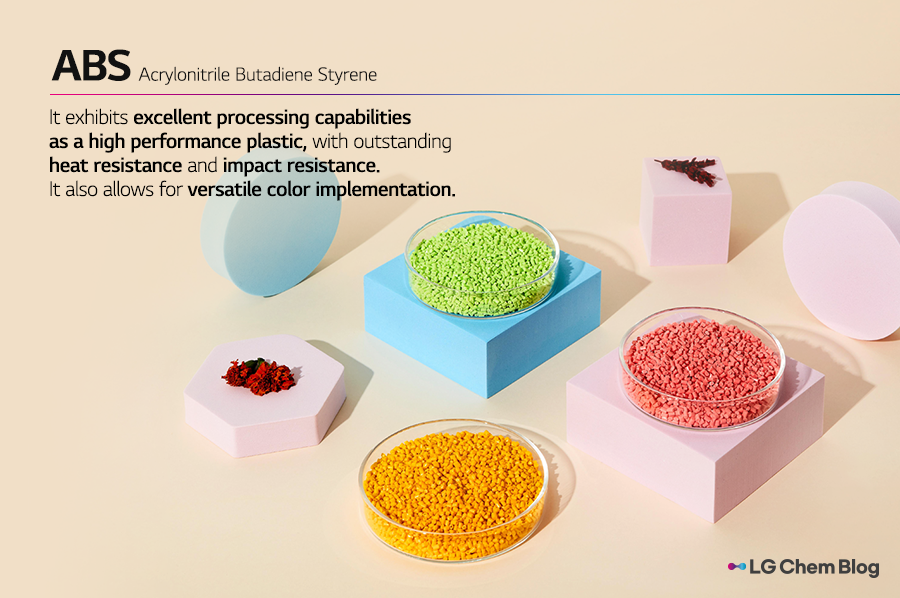

Could you please briefly explain what LG Chem’s ABS is?

•Seo-Hwa Kim (PL), Kim Chang-sool (Team Leader): ABS (Acrylonitrile Butadiene Styrene) is one of the key plastic products developed by LG Chem’s Petrochemicals Business Division, holding the top global market share. ABS is a high-performance plastic known for its excellent impact resistance, heat resistance, and appearance. It exhibits exceptional processability and can be molded into various shapes and colors. LG Chem produces 2.05 million tons of ABS annually worldwide, and it is used as a material in a wide range of products, including household appliances, office equipment, automotive interior/exterior parts, and toys.

So, what is the PCR-ABS material that you both are collaborating on for development and research?

•Seo-Hwa Kim, PL: PCR material stands for Post-Consumer Recycled material, which is a type of plastic material produced by recycling plastics that customers have used and discarded. It involves collecting and processing plastic waste from end-consumer products, such as shredding and separating the plastic, and applying our researched technology to create a new material. Our research objective was to develop PCR ABS that could meet the same level of quality as traditional plastic (ABS) materials. Currently, the products made from PCR ABS exhibit such high quality that they are visually indistinguishable from those made from traditional plastics.

What motivated you to undertake this project?

•Seo-Hwa Kim, PL: Global plastic production amounts to approximately 390 million tons annually (as of 2021). However, only about 40% of this is collected for recycling purposes. With the goal of reducing plastic waste and creating environmentally friendly products, we embarked on the research and development project for PCR ABS.

•Chang-Sul Kim, Team Leader: Firstly, we recognized the significant market potential of PCR ABS products. As environmental regulations become stricter in various countries worldwide, there is a growing business trend of using recycled plastics as raw materials. Moreover, it presents an opportunity to involve consumers in a circular economy, alongside companies, adding value to their participation.

There are various methods of recycling plastic. What are the different recycling methods and how do they work?

•Seo-Hwa Kim (PL), Chang-Sul Kim (Team Leader): That’s correct. There are several methods for recycling plastic, including mechanical, chemical, and thermal recycling.

Firstly, mechanical recycling involves changing the physical form of collected plastic without altering its chemical structure. The collected plastic is sorted into the same type of plastic material and then reprocessed. This method is applicable to certain polyolefins and PET materials.

Chemical recycling, on the other hand, involves changing the chemical structure of the recycled plastic to regenerate it into raw materials. However, applying this method to resins with complex compositions like ABS can be challenging, as it requires complex reactions and processes. Therefore, it is limited to plastics composed of single materials such as PE (Polyethylene), PP (Polypropylene), and PS (Polystyrene).

Lastly, thermal recycling utilizes the high calorific value of the plastic itself as a heat energy recovery method. It involves incinerating plastic to generate energy, but it also produces harmful substances, resulting in relatively low recycling efficiency.

Recently, there has been increasing attention on mechanical recycling, which allows plastic to be recycled into the same type of plastic (virgin plastic) without significantly affecting its composition and structural form. We also developed PCR ABS material through the mechanical recycling method. However, it’s important to note that if different types of plastics are mixed together, the mechanical properties, appearance, processability, and other characteristics of the plastic can be significantly compromised, making it difficult to use. Therefore, it is crucial to separate plastics by type to achieve higher purity.

What is the process of developing PCR ABS?

•Seo-Hwa Kim, PL: The development of PCR ABS involves several steps. Firstly, we receive discarded electronics, plastic products, and other materials from specialized recycling companies, which are converted into pellet form, the initial raw material stage. The first crucial step is sorting the provided pellets, particularly ABS, among the various types of plastics such as ABS, PP, PE, and PS. With advancements in separation technologies driven by the increasing global demand for plastic recycling, we employ these technologies to remove impurities and ensure high purity during the separation process. The resulting recycled material is then mixed with virgin materials to create the final PCR-ABS product.

What are the technological capabilities and unique advantages of LG Chem’s PCR ABS in this research and development?

•Seo-Hwa Kim (PL), Chang-Sul Kim (Team Leader): LG Chem’s PCR ABS possesses several technological capabilities and unique advantages. Firstly, we have developed the capabilities to produce PCR ABS at a level comparable to that of conventional plastics. Additionally, we have achieved a breakthrough in producing white-colored PCR ABS, which is a significant advancement. Previously, due to the nature of waste plastic, recycled plastic products often had mixed colors, resulting in darker shades like black or gray. The recycled plastic materials supplied by our collaborating companies for PCR ABS development were mostly in black or gray colors, posing challenges in achieving high whiteness in the final product.

To overcome this challenge, our research team and color design team set a target color value and meticulously examined LG Chem’s existing technologies to bridge the gap between the target value and the actual value. Our research direction focused on the selection and blending of white pigments and the development of core formulations to enhance whiteness. Through extensive research and analysis, we discovered that the material used for the interior walls of refrigerators exhibited excellent whiteness compared to other materials. Building on this insight, we devised our unique solution and successfully obtained the final PCR ABS with the desired whiteness.

If there were any difficulties during the research and development, what were they? And what is needed for a more advanced future?

•Seo-Hwa Kim, PL: The research and development of PCR presented unique challenges compared to developing new products. Dealing with materials that have uncontrollable characteristics posed difficulties despite our efforts to enhance their properties. Challenges such as color, impurities, and properties of the PCR source (the final product used by consumers) had limitations that were not easily overcome. These uncertainties and doubts about surpassing the limitations of PCR products and creating satisfying customer products were perplexing during the early stages of research.

Fortunately, we overcame many challenges and succeeded in product development. However, for the long-term sustainability of the PCR material market, it is crucial to secure as many cleanly sorted PCR sources as possible. To achieve this, it is essential to consider reusability from the development stage of plastic appliances by selecting materials, product structures, colors, etc., that facilitate easy separation and disposal. Additionally, policy measures are needed to establish a system that promotes plastic circulation.

•Chang-Sul Kim, Team Leader: From the perspective of establishing a resource circulation ecosystem, deriving new ideas for product development posed challenges. It was not an easy task to create products that go beyond simple blending of recycled resins and meet customers’ expectations.

Of course, the joy of finding solutions to challenging problems is indescribable. However, building a global circular ecosystem requires significant policy support. It is necessary to communicate that recycled plastics are not waste but an integral part of sustainable lives and provide incentives to customers who contribute to recycling. Active support for policies that foster medium-sized companies participating in building a recycling ecosystem is also essential.

Lastly, please tell us about your vision and goals for the future!

•Seo-Hwa Kim, PL: After facing numerous challenges and putting in relentless effort, we successfully completed the development of PCR technology in June 2020. We achieved the ability to produce PCR materials on the existing ABS production line. Currently, our focus is on introducing new products to various customers while considering their specific requirements in terms of form, design, and color. Our goal is to develop PCR materials that meet these specifications and successfully deliver them. Furthermore, to secure a leading position in the emerging PCR ABS material market, we aim to develop materials with higher PCR content following this initial development. Our ultimate vision is to develop recyclable plastics by diversifying the sources of PCR materials, incorporating new colors suitable for PCR materials, and conducting continuous research and development. We aspire to contribute to LG Chem’s sustainability strategy by promoting various forms of easy reuse.

•Chang-Sul Kim, Team Leader: In reality, it feels like we are just at the beginning stage. However, one thing is clear: recycling should provide benefits to customers. We need to apply advanced technologies that ensure recycling is advantageous to customers, rather than merely creating products for the purpose of recycling. It is crucial for us to collaborate with customers to establish a proper circular ecosystem. We will strive to introduce transparent recyclable products in the market and actively seek ideas and solutions by considering real-life situations to make recycling more customer-oriented.

Plastics are no longer considered mere waste; they hold intrinsic value and contribute to social welfare. To realize this potential, individual efforts from users, coupled with policy support and active research and investment from companies, are vital. We remain committed to spearheading sustainable material research and establishing a circular resource ecosystem that encompasses plastics.

There are no comments yet! Be the first to let us know your thoughts!