LG Chem in Automobiles! Introducing the status of automotive materials development

2024. 08. 28

LG Chem in Automobiles! Introducing the status of automotive materials development

2024. 08. 28

We meet materials developed by LG Chem in every corner of our lifestyles. ‘Automobiles,’ an indispensable part of our lives, is of no exemption. LG Chem produces the materials for various automotive parts, from adhesives to car seats, interior/exterior materials, and EV batteries. Here are the case stories of LG Chem’s products applied to cars.

LG Chem is taking part in the decarbonization project run by a European premium EV brand. The project aims at producing climate neutral cars by 2030. From material production to development of parts, processing, and delivering the final product to customers, the goal is to make carbon emissions ‘zero (0)’ across the whole process.

Through this project, LG Chem plans to develop and supply eco-friendly plastics that will later be applied to the EV brand’s automotive parts, such as the interior/exterior. The two partners will conduct long-term meetings to analyze the material development, manufacturing process, and energy used, etc. to seek means of reducing their carbon footprints.

By 2025, LG Chem will partner with not just the EV brand, who is at the center of the project, but also other groups to find solutions to carbon reduction. By 2027, they plan to run a pilot project focused on automotive materials and supply chain. Finally, by 2030, the company aims to secure the production facility where they can mass-produce climate neutral cars.

To make this project a success, LG Chem is willing to take the lead in carbon reduction, based on their decades of know-how in materials R&D and technologies related to eco-friendly materials. Adding to this, the company plans to expand their eco-friendly material solutions.

The vehicle in above image has been used to explain automotive parts, with no relation to the content.

LG Chem’s Heat-resistant ABS will be supplied to a Korean automotive company, first time in the country. Heat-resistant ABS is a material that boasts excellent processability and painting properties, realizing a sophisticated and stylish design of a car. Lighter than the conventional PC/ABS, it enhances fuel efficiency and cuts down carbon emissions, contributing to making a sustainable environment. Furthermore, it has high heat-resistance and optimal balance of the physical properties, offering durability that can satisfy its users.

LG Chem’s Heat-resistant ABS is applied to the trunk lid garnish and back panels of many automotive brands. By switching their material to LG Chem’s Heat-resistant ABS, this Korean brand has improved the defects in painting and molding, which were some of the quality issues they had regarding their products. This helped them reduce the loss cost by lowering their defect rate. To do this, LG Chem used the same material as existing automotive parts for a thorough comparison/analysis of their Heat-resistant ABS, verifying the improved results with a quantitative 3D scanning value. The result proved that using Heat-resistant ABS could improve over 10% of the painting defect rate compared to the conventional material.

In the automotive industry where OEM registration is critical, LG Chem’s supply of heat-resistant ABS holds significance by laying a foundation of further application to new and other cars. Not only LG Chem, but also the automotive company is expected to provide improved products and services to their customers.

The vehicle in above image has been used to explain automotive parts, with no relation to the content.

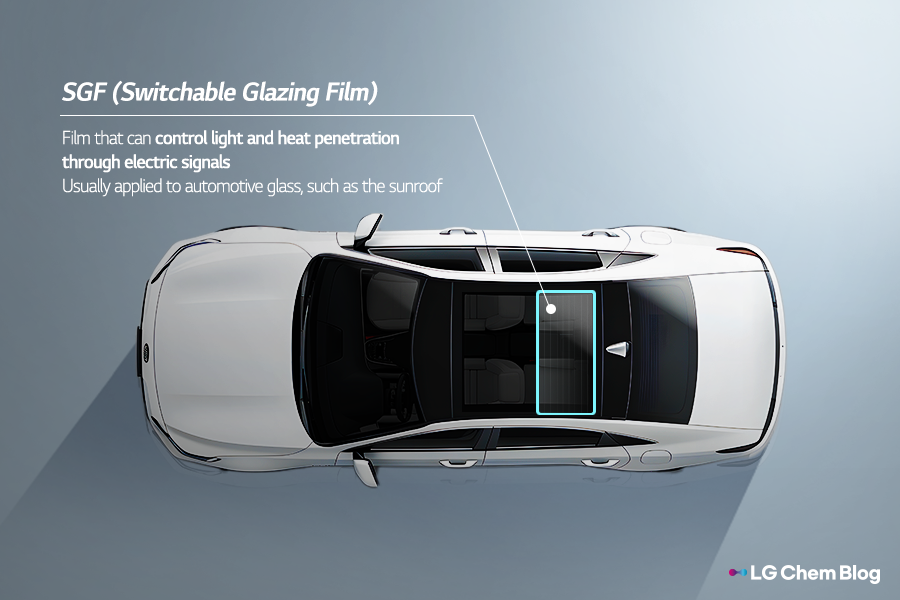

LG Chem signed a contract to supply SGF (Switchable Glazing Film) to a leading global company who produces automotive sunroof systems and is chosen as world’s Top 100 electric parts supplier. SGF is a film that can control light and heat penetration through electric signals, usually applied to automotive glass, such as the sunroof. Its original color is opaque, but it turns transparent when voltage is applied. By using SGF in a car, we can divide the glass into transparent and opaque sections. This means we can shade certain parts of the window, ensuring privacy in the car. Recently, an increasing number of premium cars and EVs are applied with SGF.

LG Chem possesses more than 200 domestic and international patents for SGF, with technologies and know-hows they have accumulated in the field of electronic materials, including display and semiconductors. Compared to its competitors, LG Chem’s SGF shows weaker light interference, offering a clear view from whichever direction. Moreover, LG Chem has procured the SGF production facility enough to cover annual 3 million cars.

This is not the end, for LG Chem is targeting at developing next-generation SGF with a vivid black color and quick response speed, and expanding the application of SGF to front and side glasses.

Today, we introduced LG Chem’s product used in diverse automotive parts. Please look forward to LG Chem’s future as they foster the mobility materials business, one of the future growth fields, based on the company’s technologies in electronics including display and semiconductors.

There are no comments yet! Be the first to let us know your thoughts!