LETZero Encyclopedia: OBP – Recycled material made up of marine waste

2024. 07. 12

LETZero Encyclopedia: OBP – Recycled material made up of marine waste

2024. 07. 12

Welcome to LETZero Encyclopedia, an introductory series to LG Chem’s eco-friendly brand LETZero and their products. Last time, we focused on PEC made with recycled raw materials.

Every year, over 12 million tons of marine wastes flow into the ocean. 80% of these wastes come from land. Plastic wastes generated near the shore may flow into the ocean due to rain, wind, tide, flow of river, and flood. These wastes are called OBP (Ocean Bound Plastic). OBP refers to plastic wastes of all sizes that are discarded within 50km of the shore region.

OBP, plastic waste flowed into the ocean, can be recycled through the process of selecting, sorting, and washing. Also, we can preemptively prevent plastic from flowing into the ocean and becoming marine waste. This way, we can protect the marine life and ecosystem.

To protect the marine ecosystem, LG Chem produces recycled plastic using fishing nets and PET bottles discarded within 50km of the shore. Let’s take a look at how LG Chem collects and recycles OBP.

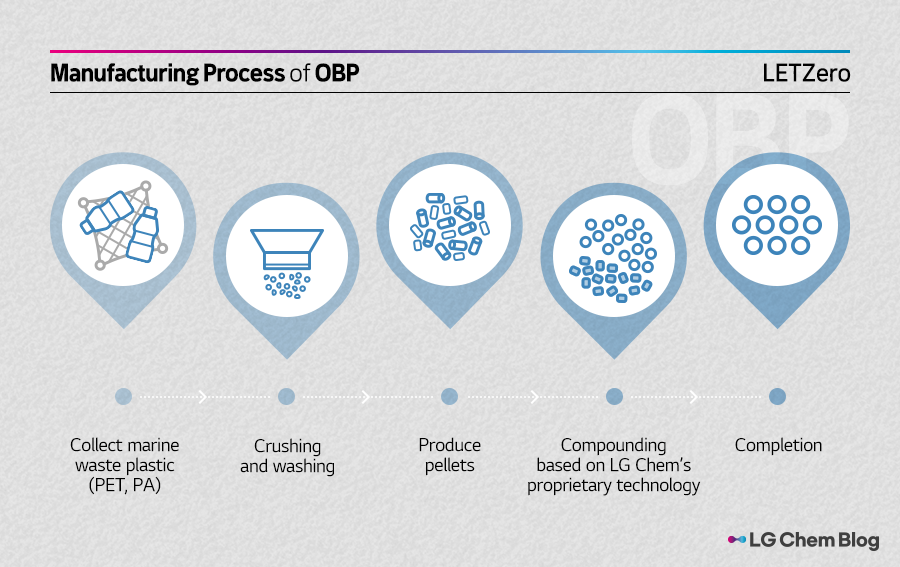

In order to recycle OBP, we first need to collect plastic wastes discarded within 50km of the shore. These wastes mostly consist of fishing nets (PA) and bottles (PET). Then, the wastes are sorted by material, color, etc. After crushing and washing, we remove the contaminants remaining in the fishing nets and PET bottles. The material cleansed through this process is made into pellets and blended with the raw material applied with LG Chem’s proprietary technology, until we obtain the complete OBP.

As OBP is made by collecting plastic waste that might flow into the ocean, it helps protect the marine ecosystem by preventing the generation of marine waste. One advantage of OBP is that it recycles fishing nets and PET bottles that take the biggest portion of marine waste to produce various products like PET, OBP PA, etc. Also, the entire supply chain of OBP, from collection of waste plastic in the ocean to management, recycling, and final production, gains verification from an eco-friendly certification and evaluation organization.

The raw materials of OBP are classified into three categories by the range of where the waste plastics are collected: Shoreline OBP, Waterways OBP, and Potential OBP. Shoreline OBP refers to wastes floating in the sea within 200m from the shore, and 100m at a low tide. Waterways OBP are wastes collected within the 200m range that stretches from the riverside to inland. Finally, Potential OBP refers to the wastes that remain unmanaged within the 50km range from the ocean to inland. LG Chem recycles the third group of OBP, that is, Potential OBP.

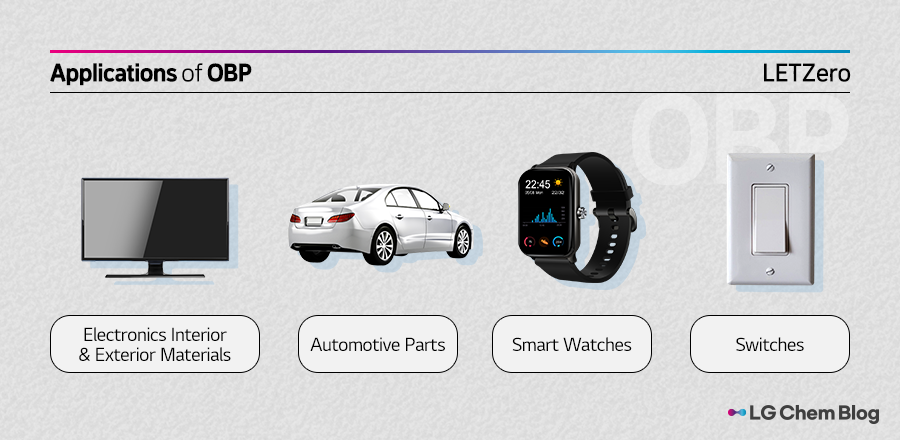

OBP collected from the sea is combined with different engineering plastics through LG Chem’s proprietary technology. It is then applied to various industries from the interior and exterior materials of electronics to automotive parts.

In specific, waste fishing nets can be recycled to create smart watches and switches, while waste PET bottles can make the material for diverse electronic devices. Furthermore, both fishing nets and PET bottles can turn into automotive interior and exterior materials.

So far, we took a look at OBP. The next LETZero Encyclopedia will come back with the story of COMPOSTFULTM.

There are no comments yet! Be the first to let us know your thoughts!