LETZero Encyclopedia: PEC – Eco-friendly plastic made of carbon dioxide

2024. 06. 21

2024. 06. 21

Welcome to LETZero Encyclopedia, an introductory series to LG Chem’s eco-friendly brand LETZero and their products. The last episode introduced PCR PVC, a material made by utilizing recycled raw materials. Today, we take a look at the features and usages of PEC, a next-generation eco-friendly plastic material made by capturing carbon dioxide, known to us as the major cause of global warming.

While the whole world makes collective efforts to cut down carbon dioxide, the major cause of global warming, various technologies have recently been introduced that not only reduce carbon emissions but also utilize the carbon dioxide that is emitted into the air. One of these technologies is CCU (Carbon Capture and Utilization).

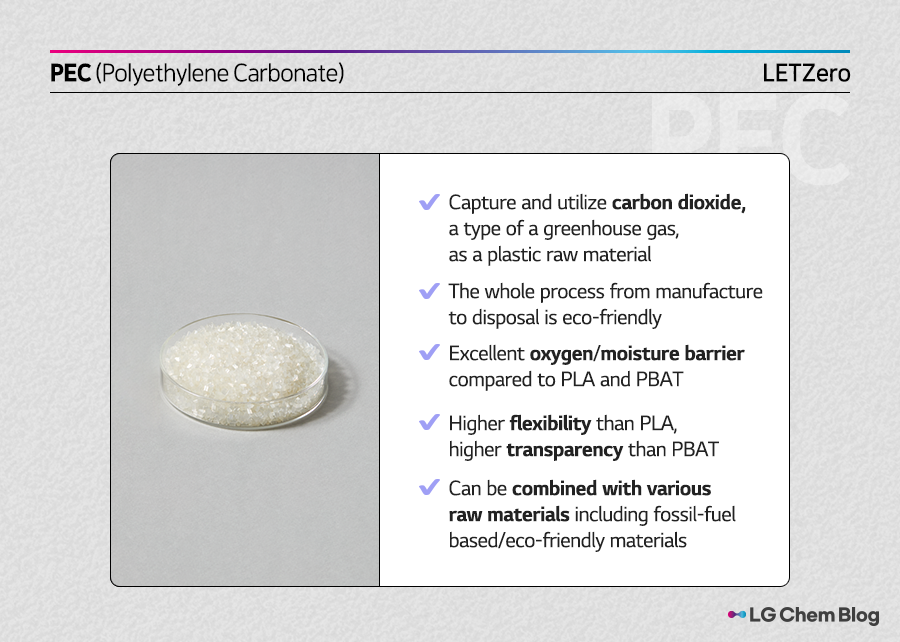

PEC (Polyethylene Carbonate) is a next-generation eco-friendly plastic material obtained through the CCU* technology. It is made by utilizing carbon dioxide captured at factories, along with Ethylene Oxide. By using carbon dioxide, a greenhouse gas, as a plastic raw material, it contributes to carbon neutrality and instant carbon reduction compared to conventional fossil-fuel based plastics.

*CCU (Carbon Capture and Utilization): a technology of capturing carbon dioxide both in the atmosphere and generated during an industrial process to utilize it as a resource

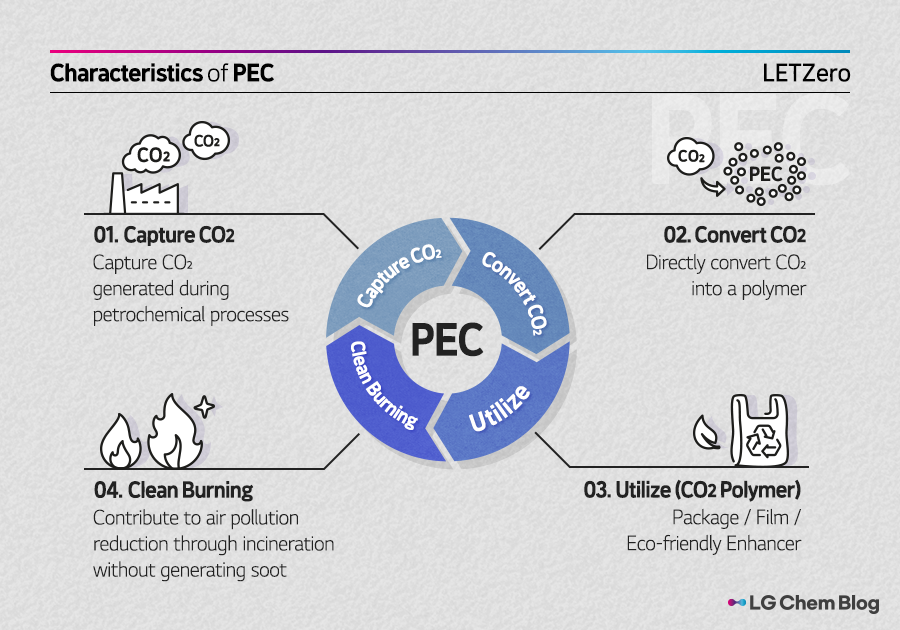

PEC is an eco-friendly material across the whole process, from manufacture to disposal. The process is as follows. First, we capture the carbon dioxide generated during a petrochemical process. By converting this carbon dioxide directly into a polymer, we make the PEC material. When converting the carbon dioxide into a polymer, LG Chem does not take a separate conversion process, but directly input carbon dioxide to obtain PEC polymers. By omitting the additional process, LG Chem can keep down the loss of carbon dioxide, producing PEC of maximum 50% carbon dioxide content. The PEC produced through this process is utilized in packaging, films, and eco-friendly enhancers. PEC maintains its eco-friendly feature until its lifespan ends and is disposed. Unlike conventional fossil-fuel based plastics, PEC is incinerated without generating soot, contributing to the air pollution reduction.

Normally, carbon dioxide is known as a stable material that is difficult to convert into another material. LG Chem has developed a proprietary material and processing technology to convert carbon dioxide into a plastic, securing the highest productivity among existing CO₂ plastics.

PEC boasts excellent physical properties, even when compared with PLA or PBAT that are widely known as eco-friendly materials. LG Chem’s PEC features superior oxygen and moisture barrier than PLA and PBAT. Plus, it has higher flexibility than PLA, and higher transparency than PBAT. Furthermore, LG Chem’s PEC can be combined with fossil-fuel based materials and other eco-friendly materials. Based on its excellent compatibility* with PLA, LG Chem’s PEC has improved its brittleness** and barrier features while maintaining its transparency.

*Compatibility: When two or more substances have affinity for each other, forming a solution or homogeneous mixture when combined.

**Brittleness: Brittleness or embrittlement, meaning that it can be broken easily

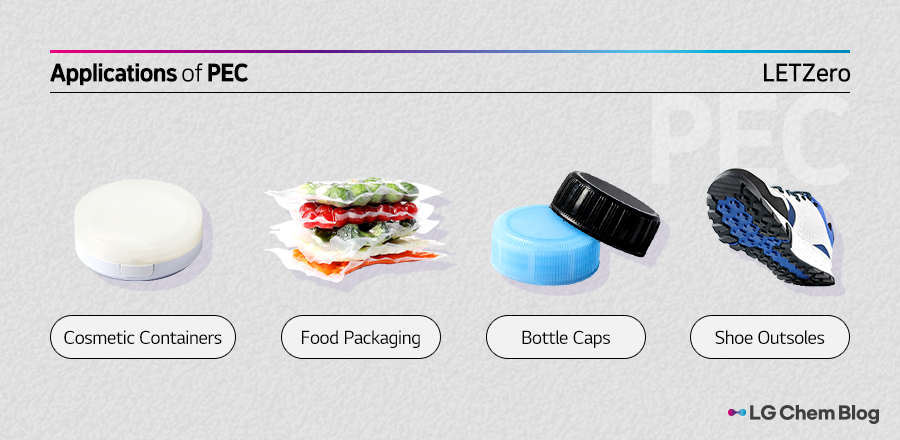

As mentioned before, PEC has high compatibility, meaning that it can be combined with various materials including PLA, an eco-friendly material, and HDPE, a fossil-fuel based material, and more. PEC blended with other materials comes with high barrier properties and transparency. It can have various applications, from flexible and soft materials to solid materials. By combining PEC with different eco-friendly and fossil-fuel based materials, we can use it to produce cosmetic containers, food packaging, water bottles, PET bottle caps, two-way stretch films, artificial leather, and shoe outsoles.

Today’s LETZero Encyclopedia took a look at PEC. The next episode will come back with a story of OBP.

There are no comments yet! Be the first to let us know your thoughts!